Plastic tubes are the ideal packaging solution for the Cosmetics, Pharmaceutical, Chemical, and Food industries.

Plastic tubes require less raw material to hold a wide range of volumes, optimizing development costs.

Plastic tubes are supplied ready to be filled. They take up less space at the POS and feature a great printing area.

They offer several possibilities for you product with different applications and a variety of diameter options.

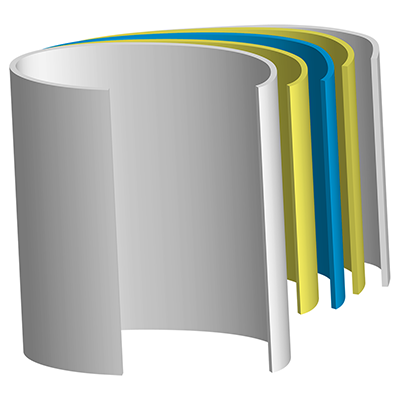

Globoplast Multi-Layer Co-Extruded (COEX) Plastic Tubes provide safety and protection for products. The ethylene vinyl alcohol co-polymer EVOH is the most efficient barrier resin against foreign agents such as humidity and oxygen, preserving the product’s integrity throughout its lifecycle.

The EVOH is introduced into the tube’s structure as a central layer in the co-extrusion process, adhering to the structure’s polar layers through highly compatible polymer adhesives. It is crystal clear, with high transparency and brightness, good mechanical strength, elasticity, and is highly abrasion-resistant.

Globoplast’s new range of Pump Airless Tubes feature a built-in dispensing valve. The vacuum system was designed to make filling easier and get the most out of the tube.

• Innovative design

• Vacuum operation (airless system)

• Screw cap

• Clear cap

Offset Silk-screen | High relief / Braille | Hot Stamping

Globoplast also offers special sealing options and unique designs to give the package a personalized, distinctive look.

Globoplast’s relief printing is an exclusive process that applies ink-free high relief images and texts. The same process enables the application of certified Braille information.

Globoplast Over-Shoulder (printing up to the shoulder) finishing process enables the tube’s full utilization and ensure better image quality, enhancing the product’s visual appeal.

Copyright © 2018 GLOBOPLAST by Dezz Digital. All rights reserved.